An industry in need of a change

Maintaining edge retention is the primary aim in the successful operation of an industrial blade or slitter. Too soft a material and the cutting edge will soon become worn and blunt. Too hard and edge chipping is more often the mode of failure. Achieving the right balance between wear and chip resistance, whilst maintaining a competitive price, is no easy task.

In the interest of the end user, not the toolmaker

Most blade manufacturers proclaim to produce the ‘best blades in the industry’ using the ‘best choice of materials’, substituting cold working steels like D2 for a more durable high-speed steel and, in highly abrasive applications, opting for a tungsten carbide to provide increased wear resistance. In reality, these are industry standards that have no manufacturer standing out from the crowd, leaving room to develop a market for premium high-end blades with greatly increased lifespan.

And of course, the end user wants the ever-lasting blade. A blade providing cut after cut with the least downtime possible, and Refmet Ceramics Synthetic Diamond Film is the perfect surface treatment towards meeting these goals.

Hardness without brittleness

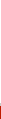

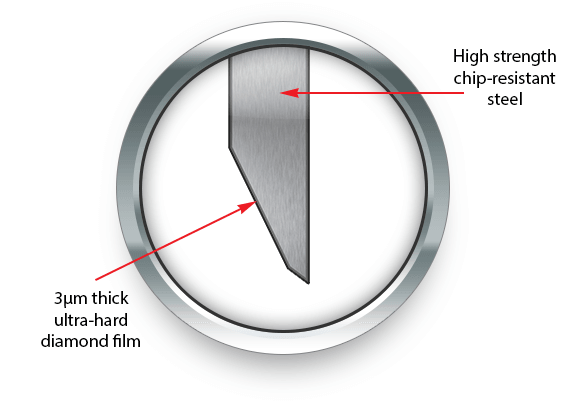

By coating existing blades and slitters with a ultra-hard and micron-thin precision Synthetic Diamond Film (SDF 24/6) the cutting edge is greatly enhanced but without instilling brittleness or compromising the original edge strength of the substrate material.

Not only does Synthetic Diamond Film dramatically increase the surface hardness by a magnitude of several factors up and beyond that of an existing steel or carbide blade, but the inherent natural ultra-low friction properties greatly assists the cutting efficiency.

Thin but tough, hard but strong.

The cutting edge of technology

Synthetic Diamond Film (SDF 24/6) is at the cutting edge of blade technology providing a blade with the necessary hardness to combat the abrasive and adhesive actions of the cutting process, whilst at the same time maintaining the original steel blade properties to provide the necessary edge strength and chip resistant qualities.

Nothing but benefits

Synthetic Diamond Film (SDF 24/6) coated blades provide:

- No change to existing blade manufacture or material.

- Longer life spans and reduced plant downtimes.

- Optimum cutting efficiencies.

- Cooler cutting temperatures with lower cutting forces.

- Inert cutting edges that resists sticking, and build-up.

Improve your blade capabilities

Check out the beneficial properties of Synthetic Diamond Film (SDF 24/6) and our other coating compositions at our coatings section and see how Refmet Ceramics can assist in improving your process and cutting efficiencies.

Learn more:

Coatings

Innovative surface coatings based on diamond, ceramics, composites and solid lubrication films.

Coatings

Innovative surface coatings based on diamond, ceramics, composites and solid lubrication films. Applications

Bearings, gears, tooling, splines, threads, punches, dies, leadscrews... discover your limitless potential.

Applications

Bearings, gears, tooling, splines, threads, punches, dies, leadscrews... discover your limitless potential.

Industries

Aerospace, motorsport, stamping, medical, vacuum, plastic moulding, sciences and many more available.

Industries

Aerospace, motorsport, stamping, medical, vacuum, plastic moulding, sciences and many more available. Contact

Contact our engineers to see how Refmet can provide a solution to your wear and friction issues.

Contact

Contact our engineers to see how Refmet can provide a solution to your wear and friction issues.