Serving the linear motion industry

As the market for linear motion systems continues to evolve, the demand for smaller equipment with increased load capacity and higher speed capabilities continues to grow. Coupled with these demanding challenges are the need to operate in more extreme environments with improved accuracies, repeatability and durability. It all calls for one thing: The industry needs a revaluation of the existing materials and surface treatments in order to take things to the next level.

Refmet Ceramics micron-precision surface technologies expands the current capabilities of lead screws, ball screws, bearings, gears, racks and pinions plus a host of other linear motion equipment by offering unrivalled ultra-low friction surfaces, with excellent environmental compatibility.

With our low temperature process and unique flexibility of deposition it is now possible to coat temperature sensitive materials and unique components such as complete bearing assemblies that were previously been deemed to cost prohibited to conduct or impossible to achieve.

Learn more:

Solid Lubrication Film

The ultimate in low friction properties with unparalleled flexibility of use.

Solid Lubrication Film

The ultimate in low friction properties with unparalleled flexibility of use.

Leadscrews

Raising the bar of efficiency, performance and accuracy of leadscrews, ballscrews, nuts and linear motion components.

Leadscrews

Raising the bar of efficiency, performance and accuracy of leadscrews, ballscrews, nuts and linear motion components.

Bearings

Ultra-low friction coatings for both individual bearing components and fully assembled ball and roller bearings.

Bearings

Ultra-low friction coatings for both individual bearing components and fully assembled ball and roller bearings.

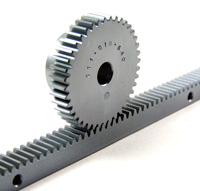

Gears

Increased efficiencies and improved power densities whilst providing a lubrication film to overcome surface fatigue.

Gears

Increased efficiencies and improved power densities whilst providing a lubrication film to overcome surface fatigue.