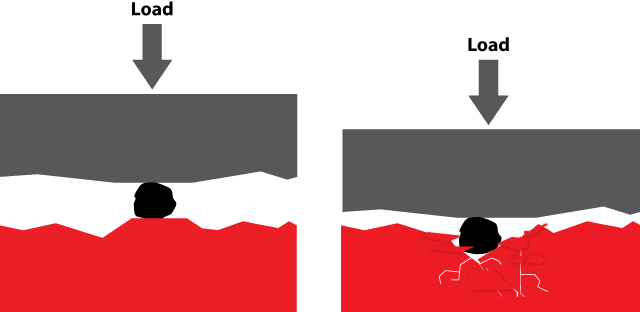

Surface fatigue wear, also referred to as rolling contact fatigue, predominantly occurs in rolling element bearings in which the bearing surfaces are subjected to repeated cyclic stress caused by clearance size particles that are harder than the steel becoming entrapped between the two moving surfaces. As the cycle is repeated the induced stresses causes the surface or subsurface to micro-crack and micro-pit, which continue to propagate between defects and inclusions within the steel which cause the material to eventually dislocate and spall. As the process continues the spalled fatigue wear particles (debris) further contribute to the wear process that leads to rapid bearing failure.