Flexibility in its true sense

With each and every application posing its own unique range of demanding tribological challenges, a “one size fits all” approach is never the right solution towards extending tool and component lifetimes.

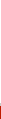

Advanced Composite Structure (ACS 24/7/74) is a new generation of thin-film physical vapour deposited (PVD) coatings that consistently outperforms conventional coatings such as Titanium Nitride (TiN), Chromium Nitride (CrN) and Titanium Carbo-Nitride (TiCN).

With the ability to adapt and optimise its key functional properties, ACS provides application specific surfaces that takes tool and component lifetimes to new and unprecedented levels of performance.

More than one specific property

The science of wear, friction and lubrication is defined as tribology and requires a multitude of properties to work in unison to combat the effects of wear.

Delivering more than one specific property, ACS 24/7/74 results in a range of optimised surface properties to overcome a multitude of tribological forces.

With variable deposition parameters, ACS provides:

- Hardness levels up to 4,000 HV

- Coefficient of friction as low as 0.05µ

- Controlled variable and uniform thickness from 2–10µm

- High temperature capabilities with excellent oxidation resistance

- Specific surface chemistries to alleviate pick-up, galling and cold welding.

- Low temperature deposition capabilities

It’s all in the surface chemistry

More frequently referred to as pick-up, galling or cold welding, adhesive wear occurs during direct metal to metal contact and the chemical affinities that lay between two materials, resulting in one material being transferred onto the other.

Acting as a permanent interfacial barrier between mating parts, ACS 24/7/74 provides a specific inert surface chemistry to alleviate the affinities from the likes of stainless steel, copper, brass and titanium that notoriously result in adhesive wear.

ACS 24/7/74 is the perfect choice for metal stamping and forming tools or similar steel components that are exposed to pick-up, galling and cold welding.

Pick-up on Titanium Nitride (TiN) compared to an ACS 24/7/74 coated surface.

Variable deposition temperatures

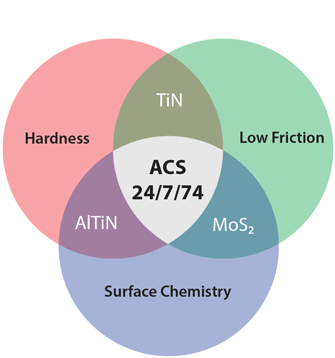

Since many coatings are deposited at temperatures in excess of 400°C, temperature sensitive tools and components are often excluded from reaping the benefits that coatings provide.

Advanced Composite Structure (ACS 24/7/74) facilitates process temperatures below 200°C, making it ideally suited to O1, D2 and other temperature sensitive materials. Such benefits ensure that parts are not exposed to thermal distortion, tempering back or have their heat treatment specification compromised.

In addition with flexible deposition parameters, ACS fulfills particular temperature critical aerospace applications where ambient deposition has become a necessity.

Case in point

Extensive trials have been conducted by several leading stamping companies to determine the benefits of using ACS 24/7/74 coated tool steel tools as opposed to using expensive tungsten carbide tools in high speed stamping applications.

In an industry driven by productivity, it was standard practice to utilise tungsten carbide in the quest for increased tool hardness in the hope of increased tool performance.

Running both tungsten carbide and ACS coated power-met (PM) tool steel tools side by side in a Bruderer high speed stamping presses, the carbide punches had undergone a total of six re-grinds and suffered from a series of micro-cracks and several broken tools after producing a total of 20 million stampings.

By comparison, the ACS 24/7/74 coated tool steel tools had comfortably produced 20 million stampings with zero regrinds, no maintenance, showed no signs of cracking and continued to produce many more stampings.

ACS has been adopted by many leading stamping companies and now seen as the industry standard in stamping and press tool coatings, with ACS replacing and significantly outperforming over PVD coatings such as TiN, TiCN, TiAlN and DLC in high volume stamping applications.

The difference that makes the difference

So what is the difference that truly makes the difference?

- The possibility to downgrade from an expensive tungsten carbide to a tool steel.

- Longer tool life and increased tool performance

- Elimination of adhesive wear

- Increased press availability and productivity

- Considerably lower tooling/maintenance costs throughout the duration of the tool life cycle

ACS 24/7/74 provides a unique set of properties that are equally as unique as the application itself and provides the ability to extend your tool and component lifetimes to advanced and unprecedented levels of performance.

Learn more:

Coatings

Innovative surface coatings based on diamond, ceramics, composites and solid lubrication films.

Coatings

Innovative surface coatings based on diamond, ceramics, composites and solid lubrication films. Applications

Bearings, gears, tooling, splines, threads, punches, dies, leadscrews... discover your limitless potential.

Applications

Bearings, gears, tooling, splines, threads, punches, dies, leadscrews... discover your limitless potential.

Industries

Aerospace, motorsport, stamping, medical, vacuum, plastic moulding, sciences and many more available.

Industries

Aerospace, motorsport, stamping, medical, vacuum, plastic moulding, sciences and many more available. Contact

Contact our engineers to see how Refmet can provide a solution to your wear and friction issues.

Contact

Contact our engineers to see how Refmet can provide a solution to your wear and friction issues.