Serving the aerospace industry

With its exacting standards, critical procedures and stringent quality requirements, the aerospace industry places the utmost of demands on reliability, performance and durability in order to satisfy the safeguards of flight safety.

Meeting a range of industry standards and specifications for dry film lubricants, including DOD-L-85645A type 1, Moog PS 202 and the latest SAE AMS 2530, Solid Lubrication Film (SLF 74/16) plays a vital role in protecting and enhancing a wide variety of aerospace components that are subjected to metal-to-metal contact and exposed to the risk of wear, pick-up, galling and seizure.

Used on gears, bearings, splines, shafts and a host of other safety critical parts, Solid Lubrication Film not only provides enhanced lubricity and improved anti-galling surfaces but also acts as a safeguard in the event of a lubrication system failure to provide an extended window of operation that enables the aircraft to be safely landed.

Deposited either as a stand-alone coating or as an enhancement to other coating compositions such as Armoloy’s thin dense chrome (TDC), Solid Lubrication Film can be found on the latest generation of both civil and defense aircraft including Airbus A380, Boeing 787 Dreamliner, and Lockheed Martin F-35 Lightning II Joint Strike Fighter (JSF).

Learn more:

Solid Lubrication Film

The ultimate in low friction properties with unparalleled flexibility of use.

Solid Lubrication Film

The ultimate in low friction properties with unparalleled flexibility of use.

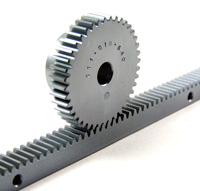

Gears

Increased efficiencies and improved power densities whilst providing a lubrication film to overcome surface fatigue.

Gears

Increased efficiencies and improved power densities whilst providing a lubrication film to overcome surface fatigue.

Bearings

Ultra-low friction coatings for both individual bearing components and fully assembled ball and roller bearings.

Bearings

Ultra-low friction coatings for both individual bearing components and fully assembled ball and roller bearings.

Threads

Conformal coatings providing threads with anti-galling and anti-seizure properties with increased pre-load torque.

Threads

Conformal coatings providing threads with anti-galling and anti-seizure properties with increased pre-load torque.