Serving the vacuum and sciences industries

The difficulties of lubricating components such as bearings, slideways, shafts, gears and screws within a vacuum environment have long been realised, and the search to provide an effective, permanent lubricant to prevent pick-up and galling from metal-to-metal contact has been the quest for engineers and scientists alike.

Refmet’s Solid Lubrication Film (SLF 74/16) is a tried and tested surface coating that provides a precision half-of-one micron lubricating barrier between moving parts with exceptionally low outgassing characteristics. Permanently bonded to the substrate material, SLF becomes an integral part of the component’s surface structure that does not migrate or contaminate under vacuum conditions.

Solid Lubrication Film’s unique and highly flexible deposition process facilitates the ability to coat tools, parts and linear motion components that were previously deemed impossible to coat.

With the ability to operate through an extensive temperature range without affecting viscosity, Solid Lubrication Film is the ideal choice for use in ultra-high vacuum applications.

Learn more:

Solid Lubrication Film

The ultimate in low friction properties with unparalleled flexibility of use.

Solid Lubrication Film

The ultimate in low friction properties with unparalleled flexibility of use.

Leadscrews

Raising the bar of efficiency, performance and accuracy of leadscrews, ballscrews, nuts and linear motion components.

Leadscrews

Raising the bar of efficiency, performance and accuracy of leadscrews, ballscrews, nuts and linear motion components.

Bearings

Ultra-low friction coatings for both individual bearing components and fully assembled ball and roller bearings.

Bearings

Ultra-low friction coatings for both individual bearing components and fully assembled ball and roller bearings.

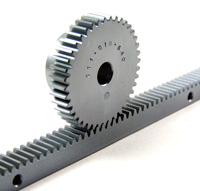

Gears

Increased efficiencies and improved power densities whilst providing a lubrication film to overcome surface fatigue.

Gears

Increased efficiencies and improved power densities whilst providing a lubrication film to overcome surface fatigue.